Thank You Wiltshire Council Alan Payne photos courtesy Carol Payne February 2020

If you come up to the Old Jockey, you will find that the road has been largely resurfaced. It was a massive effort involving a dozen people and some enormous vehicles to get the whole operation completed within a day.

Maintenance of the King’s highway has always been of major importance. The Saxons made it part of the laws of the country under the Laws of King Ine and Alfred the Great. The Stuarts placed the burden of responsibility on each parish under the control of the Surveyor of the Highways. Our Georgian ancestors privatised the system with fees payable on toll roads for all except for foot passengers and those on royal duties.

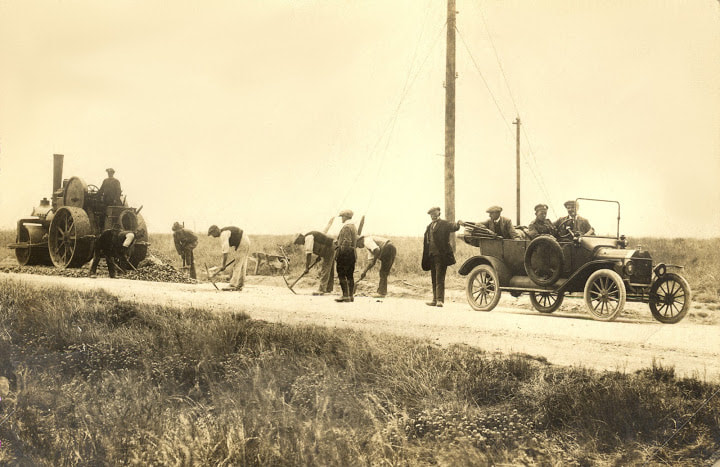

Maintenance always involved substantial manpower but the methods used in those early years were very different to today. Until modern times, repairing meant removing protruding stone and in-filling with smaller ones pressed down in the hole. With the advent of steam engines, the surface became much flatter. In the wonderful photograph below we can see the system about a century ago. When he was too old to work in the quarries, George Reeves worked as a ganger supervising the road maintenance crew in the years after the First World War.

Maintenance always involved substantial manpower but the methods used in those early years were very different to today. Until modern times, repairing meant removing protruding stone and in-filling with smaller ones pressed down in the hole. With the advent of steam engines, the surface became much flatter. In the wonderful photograph below we can see the system about a century ago. When he was too old to work in the quarries, George Reeves worked as a ganger supervising the road maintenance crew in the years after the First World War.

Modern Methods

Today’s methods are highly organised to reduce interruption to cars and other travellers. They involve scraping away about 2 inches of the old degraded surface and vacuuming away the loose debris. This is vital to ensure a clean, evenly-prepared surface, graded and correctly sloped for water run-off and to make anti-skid.

Today’s methods are highly organised to reduce interruption to cars and other travellers. They involve scraping away about 2 inches of the old degraded surface and vacuuming away the loose debris. This is vital to ensure a clean, evenly-prepared surface, graded and correctly sloped for water run-off and to make anti-skid.

Hot asphalt is brought from the mill in heated trucks to maintain temperature of about 160 degrees. Careful and slow application of new tarmac is required and any spillage removed immediately - haste is needed to finish before tarmac cools.

Then the surface is rolled many times to make it smooth. Heat radiates from the road as the work progresses.

The final touch - white lines and cat’s eyes.

If you go north out of Wiltshire into Gloucestershire you will find an enormous increase in the number of potholes in the main and subsidiary roads. So, it’s a big thank you to our council for keeping our roads maintained and our lives safer.